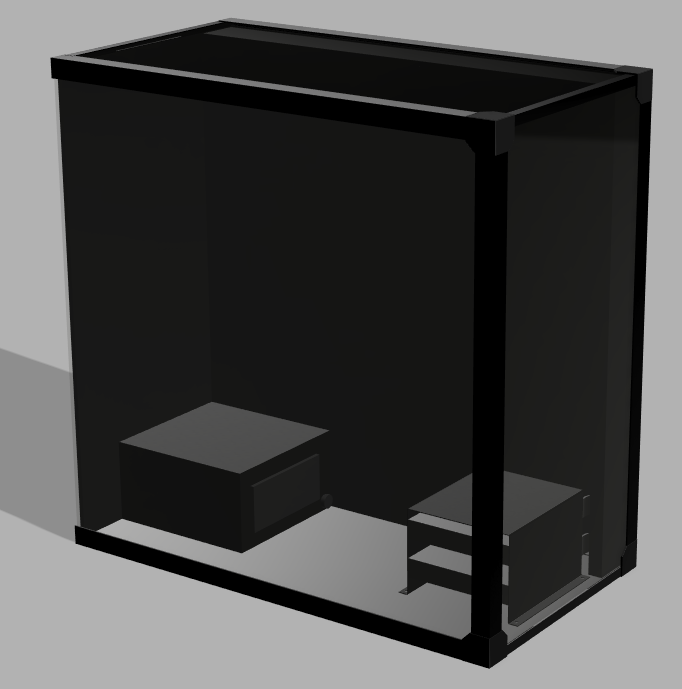

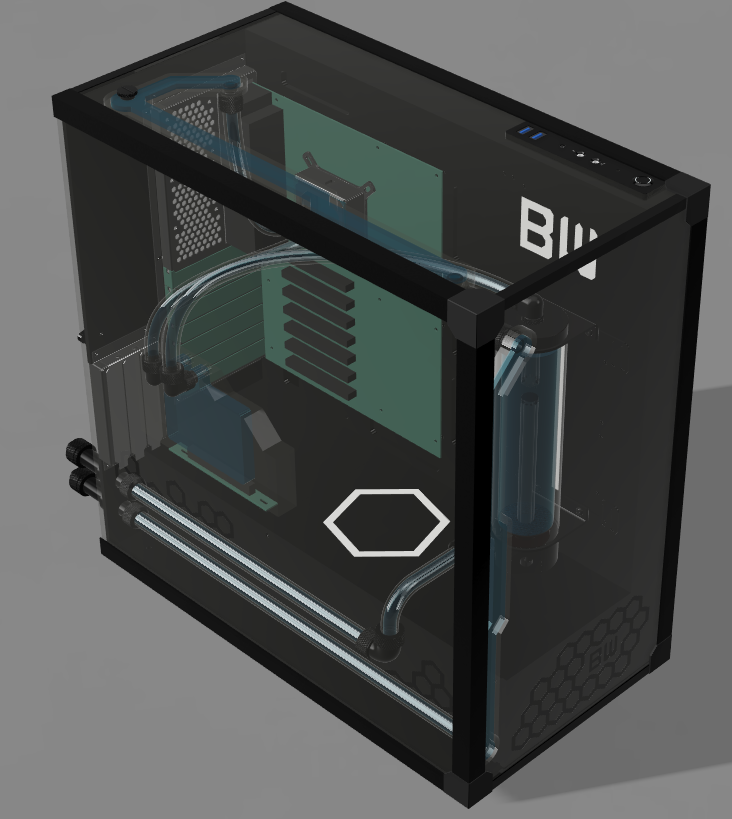

For the case design, I started with the basic wall structure, consisting of four fixed walls (top, bottom, front, back) and two removable side panels (left and right), as is typical for PC cases, as well as a central dividing wall, which would hold the motherboard later. As planned, the top, front, and left sides would be made of clear acrylic, with black acrylic used for the others.

I chose a case size of 50 x 50 x 27 cm, which was quite large for a PC case, but I had the space for it and really didn’t want it to end up cramped. The width was mostly dictated by wanting to have enough cable management space in the back, as well as comfortably fitting a vertically mounted GPU on the left side.

The edges between walls were covered with corner profiles (made of plastic and aluminium), which also served as the “rails” holding the side panels.

The placement of the power supply and HDD cage were easy too, so I placed them down right away.

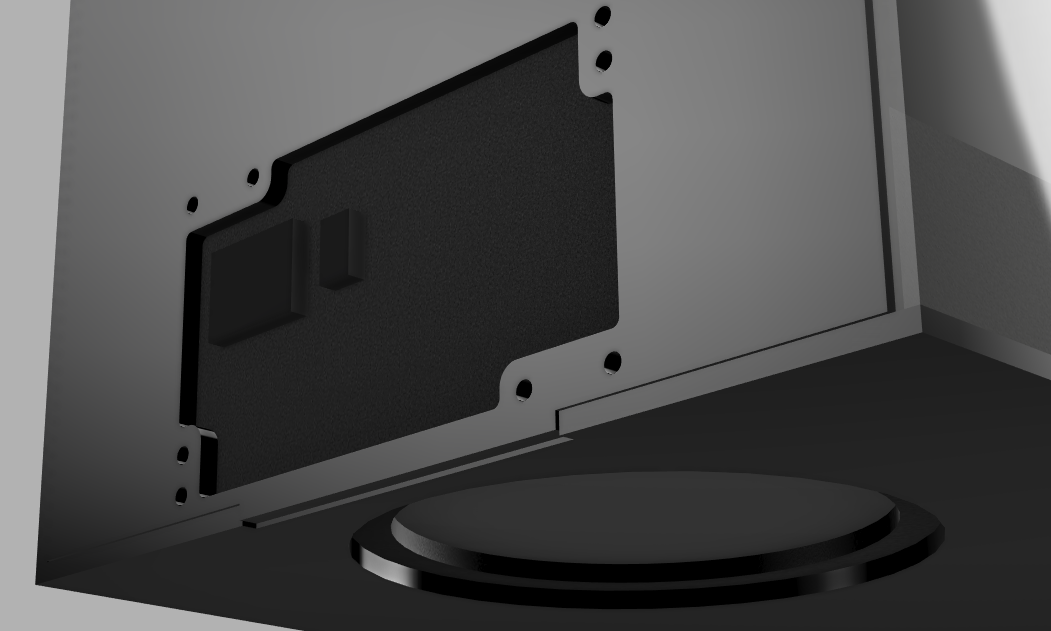

The power supply got a corresponding cutout in the back, with mounting holes allowing it to be placed with the fan facing up or down. For downwards fan placement, I also added a matching cutout in the bottom panel.

You can also see here how I added a kind of box joint at the intersections between fixed walls, allowing for a stronger bond between them later.

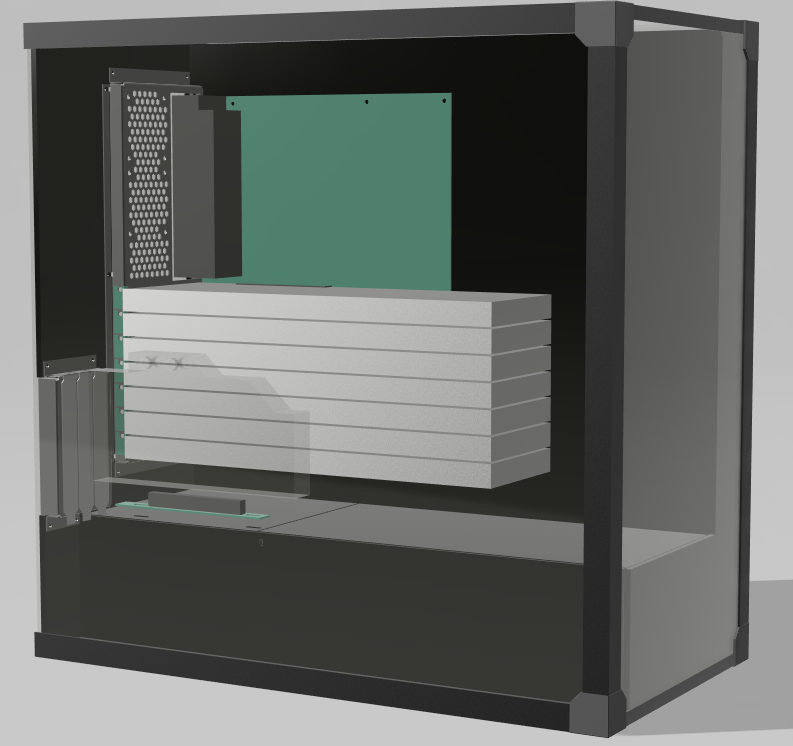

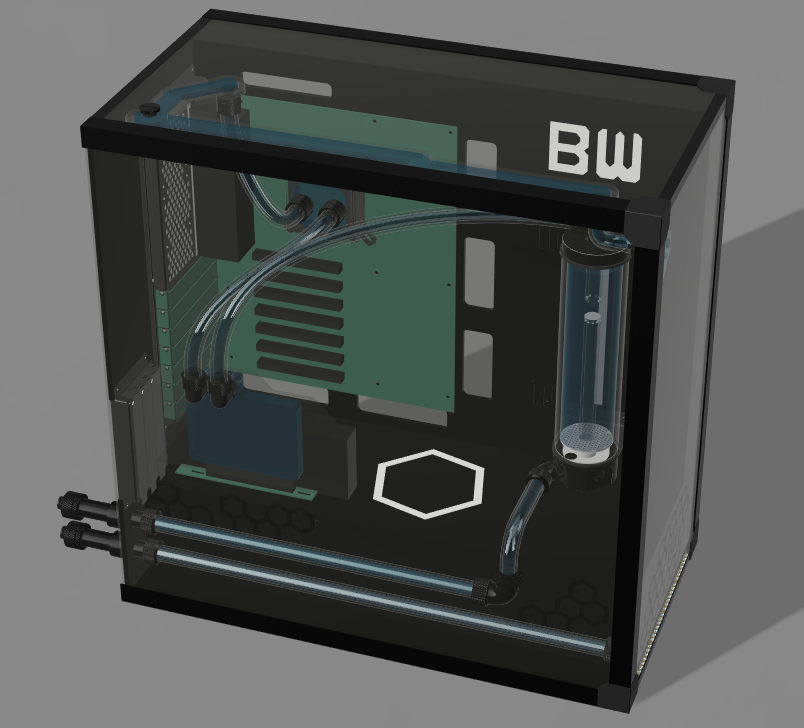

With the mock-ups for the motherboard and vertical GPU added, I now had a baseline for designing the rear I/O panels, which would be sheet metal parts designed according to the ATX and PCIe standard requirements, as discussed in the previous chapter.

The empty space on the main I/O panel was filled with a hexagon hole pattern, to allow at least a little bit of airflow into and out of the case.

Additionally, I added the lower “shelf” you can see inside the case – this would serve as a mount for the vertical GPU, but also as an aesthetic cover for the HDD cage, power supply, and corresponding cables.

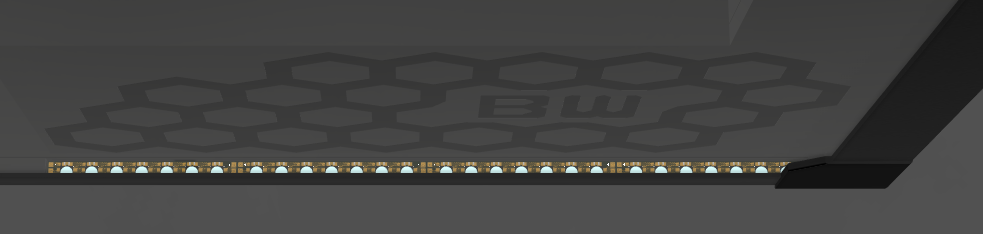

Looking at the empty space on the bottom of the front panel gave me my first idea for an aesthetic lighting feature: An engraved design and logo in the transparent panel, with LED edge lighting from below.

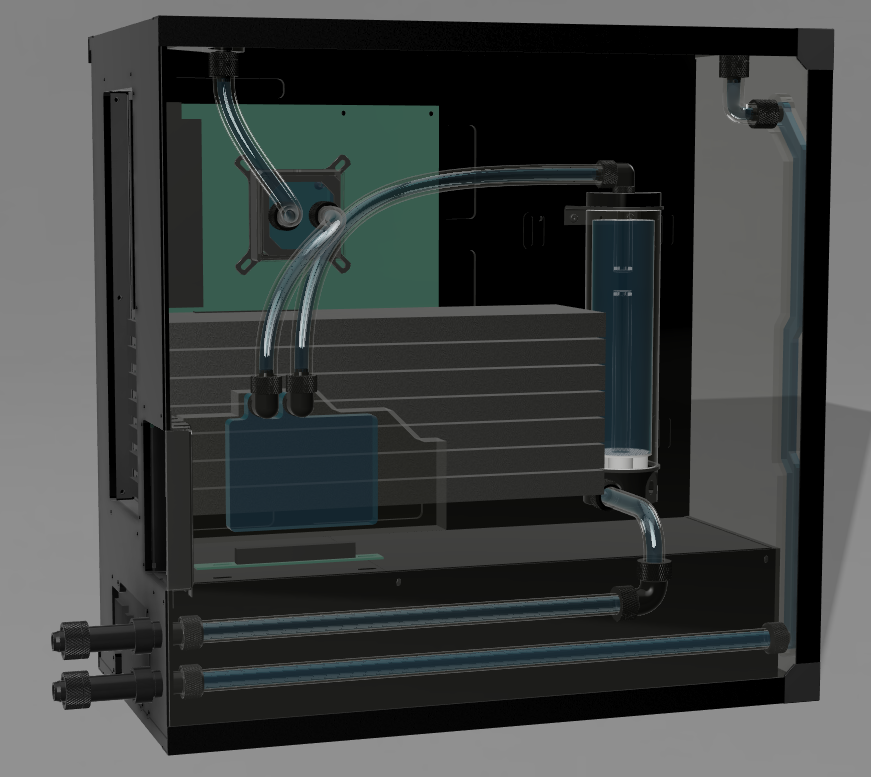

The positions of all the main PC components were fixed at this point, so I could start designing the cooling loop.

As stated in the introduction post, I wanted an external radiator, placed out of sight – same for the coolant pump. Therefore, the case itself would only contain the CPU and GPU cooling blocks, a reservoir, and coolant tubing (some of which would be replaced by channels integrated into the front and top walls).

To connect it to the external components, I added two quick-disconnect fittings on the back.

Next, it was time for some more aesthetic LED features – a hexagon accent and logo made of translucent acrylic, an LED bar behind the reservoir, as well as a few more engraved edge-lit features in the left wall.

Also, you can see that I added some cutouts in the dividing wall around the motherboard, for routing cables.

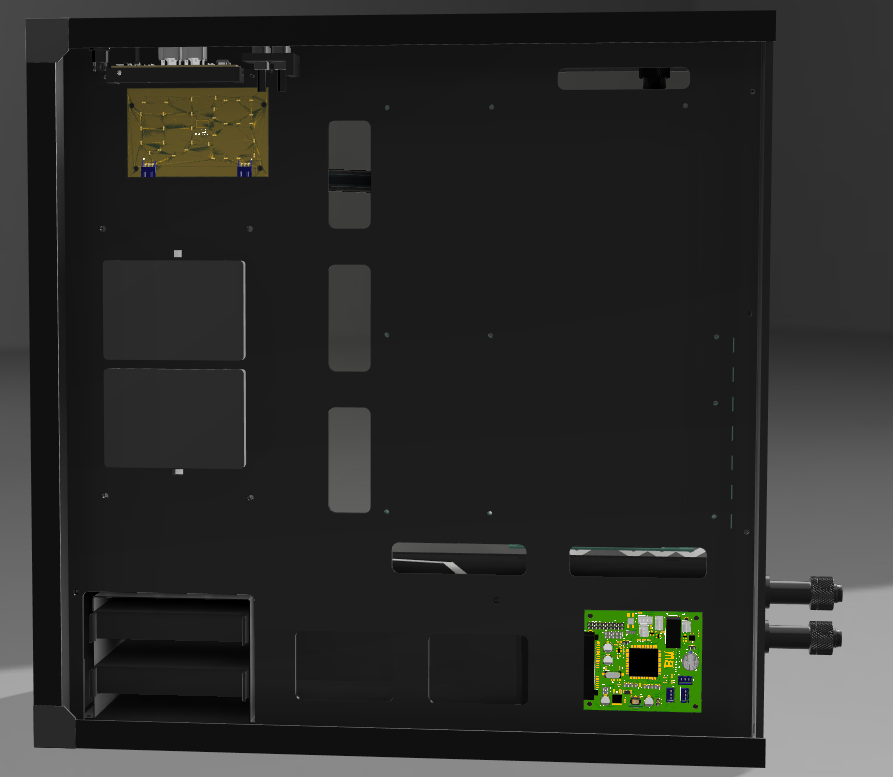

Another important part of any PC case is the front panel, which provides the power and reset buttons, the disk activity indicator, and connectors for USB and audio.

Here’s the design I came up with, on the top right of the case.

Behind the right panel, the design looked like this. Lots of cutouts and space for cable routing, access to the HDD cage, some 2.5″ SSD mounting spots, small acrylic “shelves” for the front panel electronics, and three circuit boards (logo LEDs, front panel, and case controller), which I will go into in the next chapter.

At this point, there were just a few details left to add – for example, rubber feet to support the case (while leaving an air gap for the power supply), as well as small rotatable pieces on the back side to lock the side panels into place.

With that, the basic physical design of the case was complete, and I loved how it turned out.

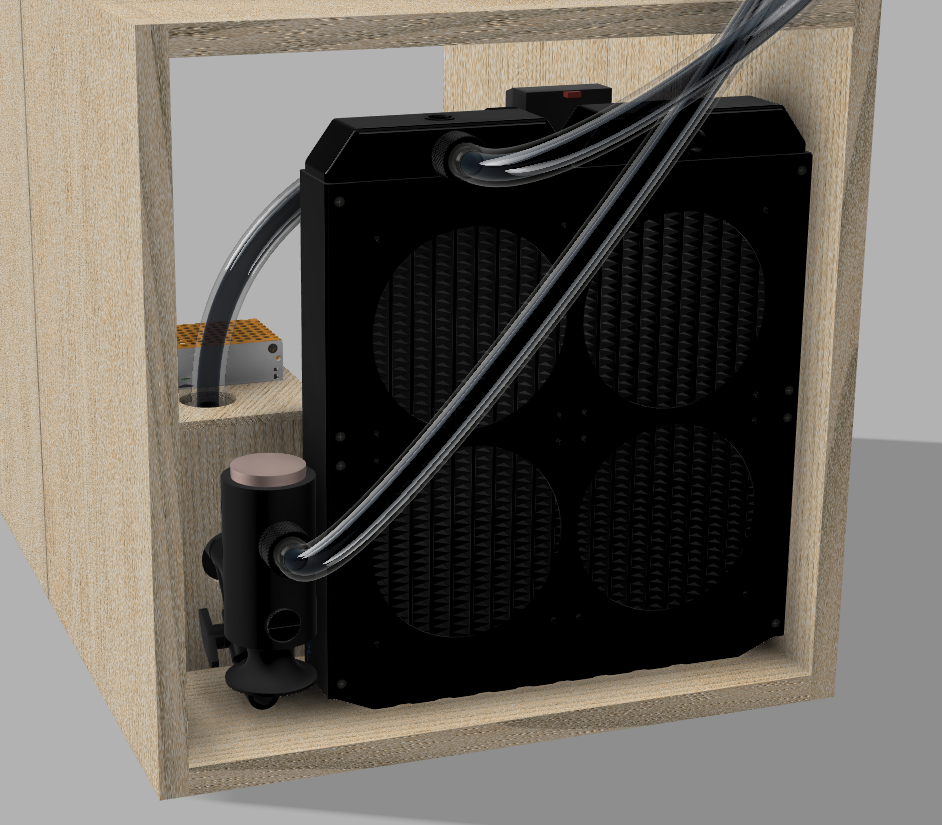

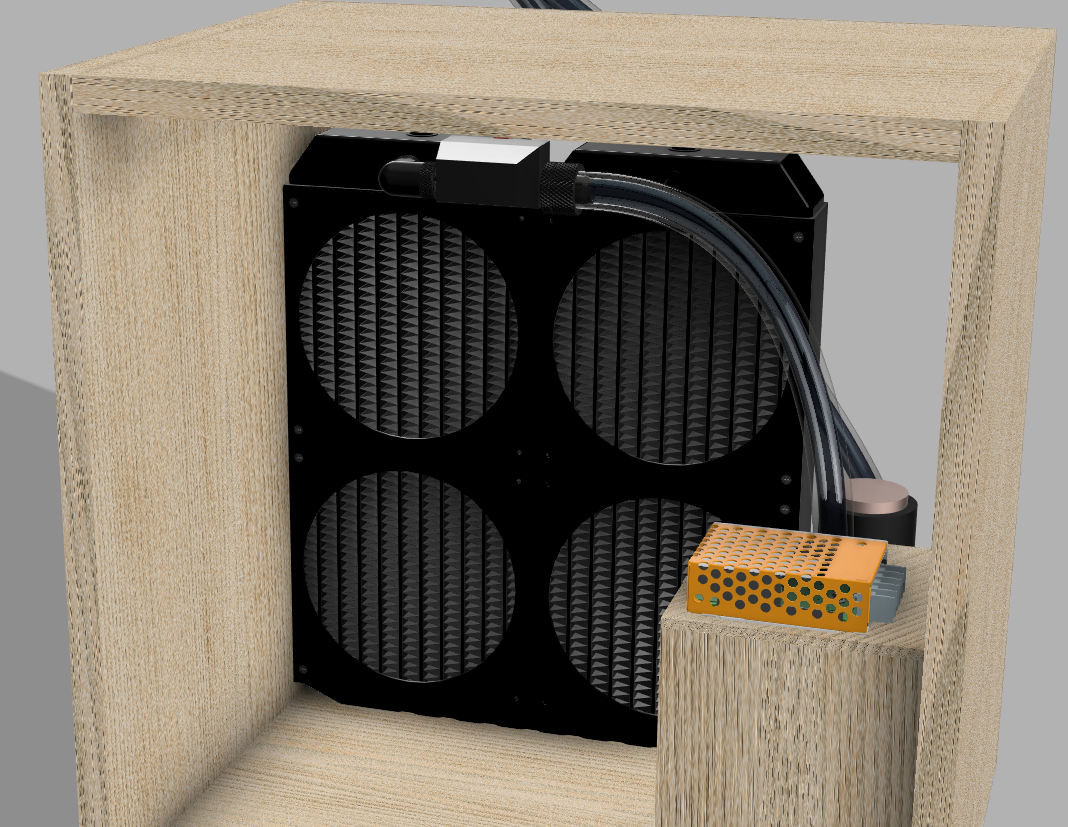

For the external cooling components, I found some simple square shelves, into which I could integrate a large square radiator (an Alphacool 480/560mm unit), a small additional reservoir, a drain port for emptying the loop, a flow and temperature sensor (Aquacomputer high flow 2), as well as a sound-dampened box for the coolant pump (initially designed for the Jingway DP1200PWM).

Placing the case on top of the shelf and connecting the external components resulted in a nice-looking overall system, with most of the “visually unpleasant” components hidden away.

Physical design done, let’s look at the electronics design next.

Leave a Reply